Dispersion capacity depends on the state of the particles and the type of incorporation.

Dispersion capacity depends on the state of the particles and the type of incorporation.

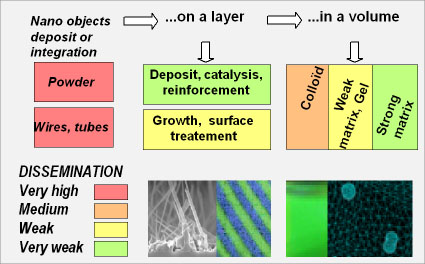

On a surface, powders are deposited for reinforcement or as a catalyst while tubes or wires are produced by growth. The bonding force of the deposited particles is very important. Wires or tubes obtained by growth are more vulnerable than powders that are deposited, their ability to disperse is more important.

In a volume, the integration is done either in a liquid medium or in a gel or a flexible matrix, or in a solid matrix. The liquid solutions (colloids) of the nano-objects are often used as intermediate products. In a non permanent matrix or in a gel, the nano-objects are less firmly fixed than in a strong matrix (e.g., ceramics).

The probability of dispersion of the nano-objects varies as the bonding force with the integration support. It will therefore be very important for dry powders, medium in a colloid, low or very low in other cases.