What are "dry powder" nanoworkshop specifications?

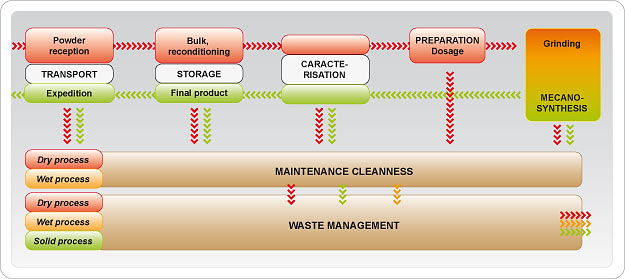

Nanomil functional process.

This platform supports applications ranging from lab scale (20 g/batch) to semi-industrial scale (2 kg/batch), in order to offer an optimized procedure for a viable industrial transfer (hygiene, safety and cost) by reducing, or indeed eliminating risks.

From a risk point of view, the platform is designed to manage the presence of "nano" precursors and/or of nanometric fraction in the powders produced.

Grinding can be performed there on all powder types (metal, ceramic, mineral, polymer) and in all types of liquid media (wet method) and gaseous media (dry method), either inert or reactive.