What are growth process nanoworkshop specifications?

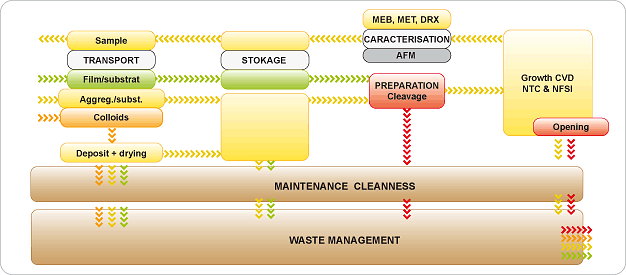

Growth functional process.

The growth equipment causes very small amounts of nanomaterials to grow on the substrate: approximately 0.01 mg.cm-2 of carbon nanotubes on a silicon wafer. The start products can be films or clusters attached to a substrate or a solution, a drop of which is deposited on a substrate.

The only sensitive phase from a safety point of view is the opening of the reactor for open maintenance.

Amongst the phases to be monitored the following may also be mentioned:

- the splitting of substrates in preparation,

- incorrect handling of an AFM tip during characterization.

- It therefore presents risk levels that are significantly lower than in powder production workshops.