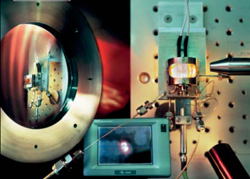

CENTURA DTNM, CVD process.

Sol-Gel Technology.

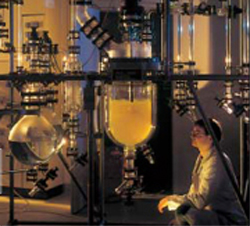

Chemical micro reactor technology.

Chemical Vapor Deposition Below a few mbars, a volatile compound and a substrate react to form a dense deposit or nanostructured organizations such as nanotubes. This reaction can be activated thermally (heating > 500°C: thermal CVD) or with the help of a plasma (PECVD) at low pressure and low temperature (< 500°C). The process is confined in a reactor, the reaction products are evacuated from the reactor by a pumping system.

Reaction in a Liquid Medium Growth under control either by the use of surfactants, or inside nanoreactors by changes in pH, T°C, and concentration conditions, etc. The non-miscible part of the surfactant is organized around the particle to limit its growth and stabilize it by a steric or electrostatic effect. If the chemical reaction takes place within micro emulsion droplets, these are considered as nanoreactors. Only an accidental reversal, or an agitation leading to the dispersion of fine droplets containing nanoparticles, is to be feared.

Sol-Gel Technology The natural processes of bio mineralization (soft chemistry), for example, use Sol-Gel techniques to produce diatoms. These processes have long been used for the manufacture of glass or ceramics. The material, originally liquid (in solution), will transform into a gel under a thermic treatment that determines the tridimensional network of nanoparticles on the gel layer. The temperature, the duration of treatment and the conditions of cooling affect the size, uniformity and distribution of the particles. The evacuation of solvents can transform the gel into an amorphous dry matter. We can then produce massive parts, protective layers or fibers that are resistant to corrosion, cementation, or more heat-resistant to increase their lifespan. Only the final phase of conditioning powders may present a risk.

Supercritical Fluid Beyond the critical pressures and temperatures, any fluid is as dense as a liquid with a viscosity as low as that of a gas. These characteristics allow:

- to recycle the solvents in the case of a chemical synthesis (limitation of effluents),

- or to facilitate the precipitation of powders by modifying the temperature to reduce the relative conductivity and thus the solubility (synthesis BaxSr1-xTiO3 (0 < x <1) or the controlled deposit of Al2O3 on BaTiO3). The useful pressures for CO2 (above 70 bars) induce risks of explosion and dispersion.

Reaction in a Solid Medium This method includes several synthesis routes which have the possibility to control the nanoparticle size. This control may be achieved thanks to initial product size, the diffusion, by specific reaction sites or by the volume of reaction .