Production reactor confinement.

Nanomil DTNM Workshop.

Sintering process.

Milling Micrometric powders (1 to 50 microns) from several alloys are milled down to a nanoscale size by agitation with tungsten or steel beads. Since 1998, INCO (USA) has produced 350 tons of Oxide Dispersion Strengthening (ODS), ZOZ (D) 600 Kg/day of a Cu-Zn welding material, APT/ANT (AUS) of ZnO nanoparticles for solar protections. Implemented in closed systems in dry phase, these processes involve high mechanical energy. The potential sources of contamination concern equipment leaks, a faulty filtration on the extractions or the recovery phases of materials.

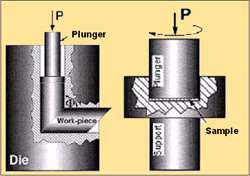

Strong Deformations A strong deformation can refine the structure of a crystalline material (metal, ceramic) to obtain grains of a few tens of nanometers in size. This technique generally can improve toughness and ductility. The risk of exposure to nanoparticles is a priori zero.

Sintering With sintering techniques, massive pieces can be obtained from pulverulent materials (metal powders, ceramics semi-conductors, and organic). Some processes developed in laboratories are currently being transferred to industry, such as microwave sintering or flash sintering under a pulsed current (msec) of high intensity (104 to 6.104 A). The most important massive pieces may have diameters of 80 cm for a few centimeters of thickness. The preparation with handling phase is critical, the confinement of powders must be ensured.