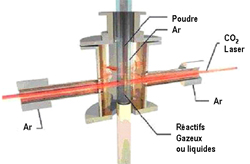

Laser pyrolysis reactor.

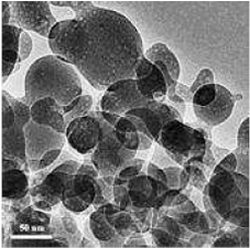

MET image of Hydroxyapatite nanopowder.

Physical Vapour Deposition Reactor.

Evaporation/Condensation under partial pressure An adequate heating (vapor pressure, surface state) evaporates a metal in a vacuum; when followed by a very fast cooling, it produces metallic and ceramic nanopowders whose growth and coalescent coagulation must be controlled. The produced aerosol must be confined (risk of dispersion) and has a high pyrophoric power in contact with air (explosion and fire).

Laser Pyrolysis The crossed jets interaction between the emission of a CO2 laser and a reagent flux causes a rapid rise in temperature and the production of nanoparticles that have a quenching effect at the burner. Most of the time, the dry powders (SIC, SiCN, SiCNAlY, SiCO, Si3N4, TiC, TiO2) are carried by a gas flux to a collector. The unloading phase is particularly delicate as regards the dispersion risk.

Thermal Plasma A plasma is a partially ionized gas (hence, a conductor) characterized by a specific glow produced when a large number of excited molecules return to the initial energy state. High pressure increases the number of collisions, which results in an increase in the energy level for all of the hot particles. The vaporized or melted particles are soaked or condensed in the form of ultra-fine particles as a result of a very rapid cooling. This process is well suited for refractory materials and/or materials synthesized with difficulty by powder metallurgy. Examples of productions: carbides (TiC, TaC, SiC), silicides (MoSi2), etc.

Physical Vapor Deposition The vacuum deposition techniques (PVD, CVD) gradually replace the galvanic processes (Zn, Cd, Cr deposits), which pollute the environment. Traditionally used in surface coatings, such processes, when associated with devices stimulating reactivity, induce the evaporation or powderisation of a metal target [TiN, CrN, (Ti, Al)N] between 300 and 550°C.

Micro-waves The micro-waves associated with synthesis routes allow the production of particles of nanometric size. A better reaction media temperature homogeneity and a rapid heating can be obtained.