Schematic types of ventilation.

Extraction breakdown.

Excessive size consequences.

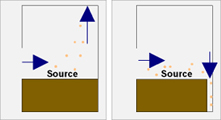

A dynamic confinement of nanoparticles can be achieved using ventilation with extraction directed up or down as needed. If the extraction functions correctly and is properly sized, the exposure of the operator is minimized. In addition, gaseous emissions are filtered to protect the environment. The maintenance of the downstream filter must respect the rules of waste management.

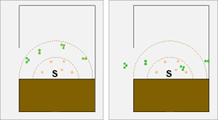

During an extraction failure, nanoparticles disperse within a certain perimeter and have a tendency to aggregate. The heaviest aggregates can be deposited. Some leaks should be expected depending on the movements of the ambient air. Leak detectors are being developed. In case of failure of the ventilation, an alarm should allow the evacuation of personnel in accordance with guidelines established beforehand.

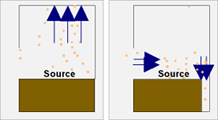

The excessive size of the pressure extraction may also be the origin of a leak of nanoparticles. The leak is then permanent and often invisible. The calculation of the extraction pressures will therefore be the subject of special attention. Using leak detectors will later allow to alert operators.